What is Electromagnetic Flow Meter?

An Electromagnetic Flow Meter (mag flow meter or magmeter) is a volumetric flow meter that does not have any moving parts and is ideal for wastewater applications or some dirty liquid that is conductive or water-based.

What is Electromagnetic Flow Meter Working Principle?

Electromagnetic Flow Meters, simply known as mag flow meter is a volumetric flow meter which is ideally used for waste water uses and other applications that experience low pressure drop and with appropriate liquid conductivity required.

The device doesn’t have any moving portions and cannot work with hydrocarbons and distilled water. Mag flow meters are also informal to maintain.

Principle of Magnetic Flow Meter Based on Faraday’s Law

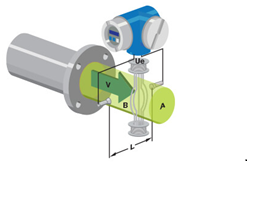

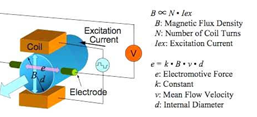

Magnetic flow meters workings based on Faraday’s Law of Electromagnetic Induction. According to this principle, when a conductive medium passes through a magnetic field B, a voltage E is generated which is proportional to the velocity v of the medium, the density of the magnetic field and the length of the conductor.

In a magnetic flow meter, a present is applied to wire coils mounted within or outside the meter body to generate a magnetic field. The liquid flowing through the pipe acts as the conductor and this induces a voltage which is proportional to the average flow velocity.

This voltage is detected by sensing electrodes mounted in the Magflow meter body and sent to a transmitter which calculates the volumetric flow rate based on the pipe dimensions.

How Does an Electromagnetic Flow Meter Works?

Magnetic flowmeters use a magnetic field to produce and channel liquid flow through a pipe. A voltage signal is created when a conductive liquid flows through the flow meter’s magnetic field. The faster the flow of the fluid, the better the voltage signal generated.

What are the Limitations of electromagnetic Flow Meters?

- The substance being measured must be conductive. Therefore, it can’t be employed for metering the flow ratio of gases and steam, petroleum products and similar liquids having actual low conductivity.

- To render the meter insensitive to differences in the resistance of liquid, the effective resistance of the liquid between the electrodes should not exceed 1% of the impedance of the external circuit.

- It is a very expensive device.

- As the meter continuously measures the volume rate, the volume of any suspended matter in the liquid will be included.

- To evade any trouble which would be caused by entrained air, when the flow tube is installed in a horizontal pipeline, the electrodes should be on the horizontal diameter.

- As a zero checked on the installation can be performed only by stopping the flow, isolating valves are required and a bypass may also be necessary through which the flow may be directed during a zero check.

- The pipe must run full, in case regulating regulators are installed upstream of the meter.

What are the advantages and disadvantages of an electromagnetic flowmeter?

The electromagnetic flowmeter offers rapid response to flow changes. It provides a linear wide range. Measuring range settings can be optimized. It has the capacity to measure reverse flow.

There are specific advantages of electromagnetic flowmeter which are given below, The electromagnetic flow meter offers rapid response to flow changes.

- It provides linear wide range.

- Measuring range setting can be optimized.

- It has capability to measure reverse flow.

- No additional pressure drops.

- No obstruction is created to flow.

- It is mostly suitable for hydraulic solid transport.

- It is genuine by changes in temperature, density, viscosity, concentration and electrical conductivity.

There are particular disadvantages of electromagnetic flow meter which are given below,

It is not suitable for low velocity.

- It is more expensive.

- It is appropriate for fluids having conductivity greater than 20 micro ohm/cm.

- Gas inclusion cause errors.

What is Applications of Electromagnetic Flow Meters?

- This electromagnetic flowmeter being a non-intrusive type can be used overall for any fluid which is having a reasonable electrical conductivity above 10 micro Siemens/cm.

- Fluids like sand water slurry, coal powder, slurry, sewage, wood pulp, chemicals, water other than distilled water in large pipelines, hot fluids, high viscous fluids especially in food processing industries, cryogenic fluids can be metered by the electromagnetic flowmeter.

Saitechflow Instruments & Control is one of the best Electromagnetic meters manufacturers and suppliers in Pun, Maharashtra, India. Saitechflow makes Electromagnetic Flow Meters of dissimilar types and these meters are field-proven. We have a calibration set up in accordance with NABL requirements. Visit Here To Know More: https://saitechflowinstru.com/