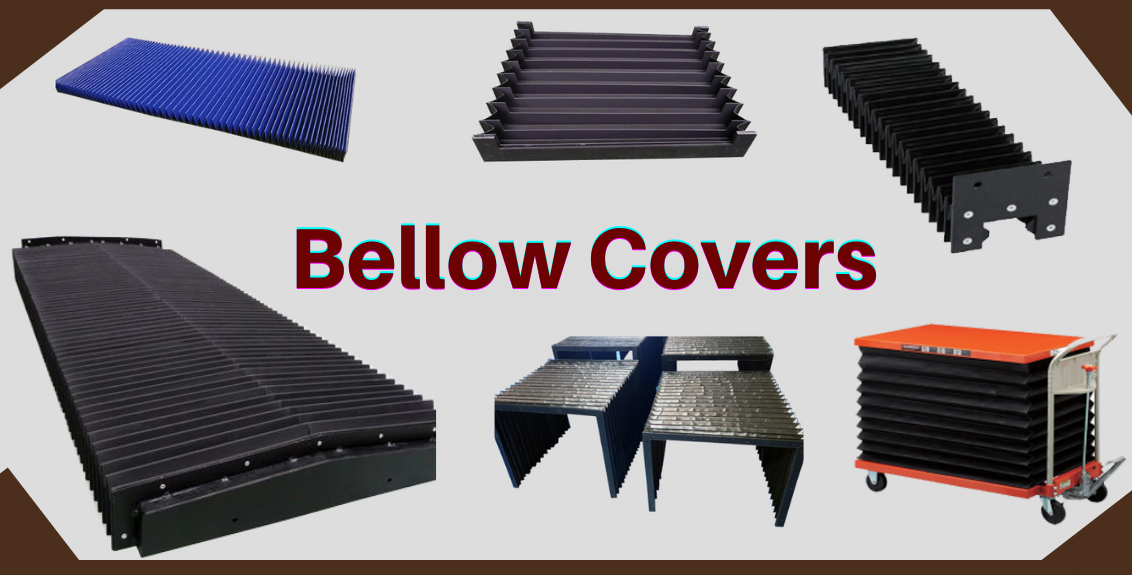

What is Bellow Cover?

A “Bellow Cover“ is Designed to protect guideways and machine components and constructed using lightweight material, bellow covers are ideal for fast travel uses. Our product choice includes modest dust protection, sophisticated designs featuring extension systems and/or lamellas, as well as special designs for laser machines.

A Bellow Cover is a cover completely out of coated textile, folded in accordion. It’s key function is to fold and unfold alongside the moving parts of the device. Depending on the usage, it can be subjected to mechanical stress, chemical aggression, high temperature, abrasion, and repetitive impacts.

Types of Bellow Cover

There are main types of Bellow Cover:

- Cylindrical Bellow Cover

- Concertina Bellow Cover

- Accordion Bellow Cover

- Scissor Lift Bellow Cover

- Telescopic Bellow Cover

- Round Rubber Bellow Cover

- Fire Proof Fabric Bellow Cover

- Trumpf Laser Bellow Cover

- Equipment Bellow Cover

- Stone Engraving Machine Nylon Bellow Cover

- CMM Machine Bellow Cover

- CNC Bellow Cover

Raw Material for Bellow Covers

A Bellow cover is a great choice when a standard way protector is needed. Bellows are easy to fit with the smallest shut length and high travel speed. These are fabricated using dissimilar grades of steel, rubber, PU coated, Foam leather, Glass fabric cloth depending upon the type & area of protection and work environment Material Used Nylon Fabric coated with polyurethane, High Tensile Polyamide Fabric, Canvas. Mounting Bellows are mounted and removed simply.

Cost of Bellow Cover

Find here the online price range of companies selling Bellow Cover INR 2,000 to 10,000 {All Tax Inclusive}.

Where to buy Bellow Cover?

So many companies in India who are manufacturers and suppliers of bellow covers but one name are really famous in this field that’s name Gurukrupa Engineering. Gurukrupa Engineering is a reliable solution provider of Bellow Cover etc. Focusing on a customer-centric approach, Gurukrupa Engineering has earned a reputed name in the field of the best grade of Industrial Bellows, Drag Chains, Apron Covers, Bellow Covers, and Telescopic Covers.

How to Choose the right Bellow for Machines Tools?

Bellows protect valuable parts of machines and workers. By protecting the guideways and device modules the bellow covers help to the proper functioning of the engines. In fact, the machine tools, machine lasers, 3D printing machines, and additional machines require protection to deal with rude environmental conditions. This is why it’s significant to select the appropriate bellow.

Types of Manufacturing Process for Bellow Covers

There are many possibilities to do a bellow and the number of these possibilities increases with the numerous types of material and shape of bellows.

HF (High frequency) welding

One of the regular processes of manufacturing there is the high-frequency welding process. This procedure comprises welding the portions of the fabric between them with a high-frequency machine.

Heat welding

This next process of welding consists of putting a plate between the plies of the fabric and weld with a high-temperature machine to dissolve the plate and to fix the different parts between them.

Gluing

The third process is the gluing process. That allows sticking the sidewalls of the fabric between them. The process is close to the High-Frequency process but the final product hasn’t a life span as the High-Frequency procedure.

Laminating

The laminating process presents a benefit it’s the capability to choose changed material to compose the product. This process provides bellows for the small machines because the fabric can be very light. But the drawbacks are the following: the product can have delamination issues and it’s an expensive procedure.

Stitching

The fifth manufacturing process is the stitching process. This manufacturing process offers high mechanical resistance to the bellow. With this process, the fabric will lose automatically the water tightness property.

Features Of Bellow Covers

- Oil and corrosion resistance

- Handiness and good sealing effect

- No electric noise

- Withstand much weight on the surface

- No metal portions inside the shield, free of losing parts that damage the machine

- Various shapes and sizes for choice

- Flexible and smooth Function

- Dust and Water Proofs

- Spatter Proof and Fire Proof

- More Length have small Compression

Specification Of Bellow Covers

- Materials are designated based on the application or operating conditions. Average materials include nylon, polyester, synthetic rubber, PVC, PTFE, PUR

- Colors vary depending on material choice

- Packing methods are required as per clients’ needs

Application Of Bellow Covers

Protective Bellows Covers are basically used in the below Areas and Sectors:

- Machine Tools

- General Industrial

- Lifting Tables

- Printing Machinery

- Medical field

- Drive protection

- Positioning

- Laser Machines

- Automation industry

- Cement Plant

- Power Plant

- Optical, etc.

Conclusion

Choosing the right material for the right situation is essential for an efficient process. In facts, good equipment will provide improved yield. By choosing the right protection the used machine will require less handling process and it will expand the machine’s lifespan.