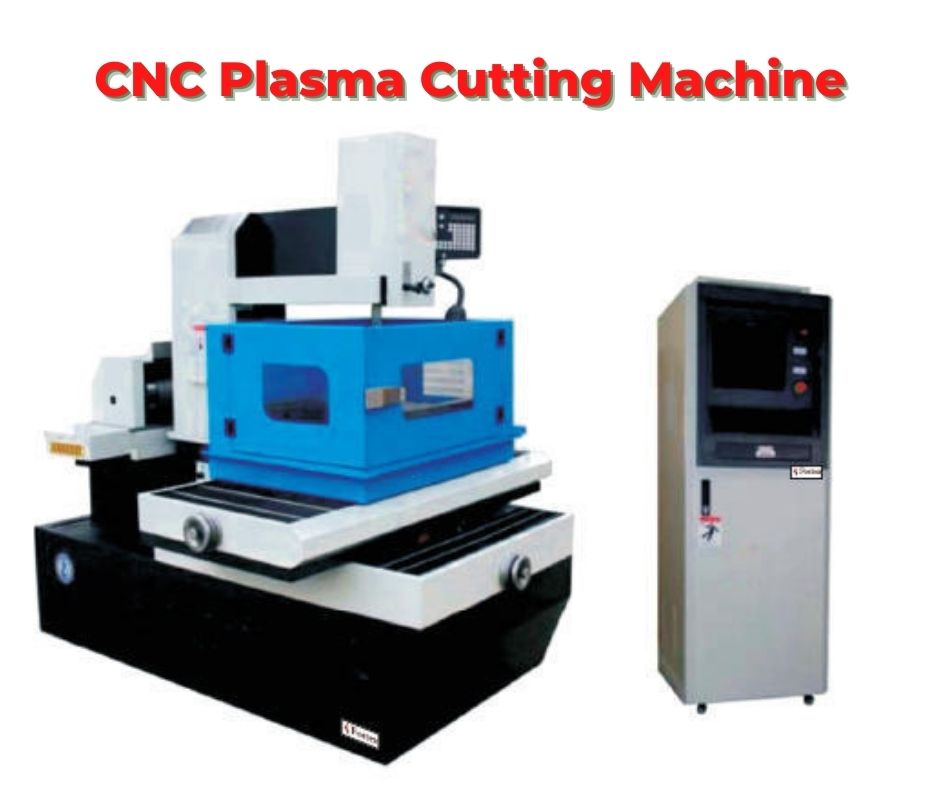

What is CNC Plasma Cutting Machine?

A CNC plasma system is a device that spreads a plasma torch and can passage that torch in a path directed by a workplace. The Term CNC is also known as Workstation Numerical Control, which means that a computer is used to direct the machine’s motion based on numerical codes in a program. Early plasma cutters were large, slow, and costly. Therefore they were mainly used for pattern cutting repetition in mass manufacture mode. For example, other machine tools, CNC (Computer Statistical Control) technology was used in plasma cutters from the late 1980s to the early 1990s.

CNC plasma cutting is a melting procedure in which jets of ionized gas at temperatures above 20000 Degree Celcius are used to melt and remove substantial from the cut. For the period of the process, an electric arc is struck between an electrode and a workpiece.

Types of CNC Plasma Cutting Machine

There are three types of CNC Plasma Cutting machines. The three key shapes of these units are the 2D/2 axis, 3D/3+ axis, and tube and sector CNC plasma cutting Machine.

1) 2-dimensional / 2-axis CNC plasma cutting Machine

This is the most average and conventional form of CNC Plasma Cutting. Producing flat outlines, where the cut edges are at 90 degrees to the material surface. High power-driven CNC plasma cutting bedsteads are configured in this technique, able to cut outlines from the metal plates up to 150 mm thick.

2) 3-dimensional / 3+ Axis plasma cutting

3-dimensional Plasma cutting machines can work on flat plates. The cutting head can be angle with the 2 axes of the CNC plasma cutting machine. Once we set the angle at the stage of nesting this angle is applied through all parts of the business, for example, we set the 40-degree angle to the square job then the 4 side has an equivalent angle torch will move according to the x and y-axis. This is commonly used in large fabrication structure who wants to escape the grinding and machining operation. Countersunk slums and chamfer edges of profiled holes are simply cut in the 3-axis machine.

3) Tube and section plasma cutting

Used in the processing of pipe, tube, or any form of long section. The plasma cutting head most lyremnants stationary whilst the workpiece is fed through and rotated around its longitudinal axis. There are several configurations where, as with 3-dimensional plasma cutting, the cutting head can tilt and rotate. This card angled cuts to be made through the thickness of the tube or sector, generally taken advantage of in the fabrication of process pipework where cut pipe can be provided with a repair preparation in place of a straight edge.

How Does a Plasma Cutter Work?

The plasma cutting procedure is a thermal cutting method. This means that it uses heat to melt the metal instead of mechanically cutting it. The overall mechanics of the method is always the same. Plasma cutters usage compressed air or further gases, such as nitrogen. Ionisation of these gases takes place to generate plasma. Usually, the compressed gases come into contact with the electrode and then ionise to create extra pressure. When the pressure builds up, a stream of plasma is pushed towards the cutting head. The cutting tip constricts the flow to make a stream of plasma. This is then subjected to the workpiece. As plasma is electrically conductive, the work portion is connected to the ground through the cutting table. As the plasma arc contacts the metal, its high temperature melts it. At the same time, the high-speed gases blow away the molten metal.

Raw Material of CNC Plasma Cutting Machine

A CNC Plasma cutting is a process that cuts the electrically conductive materials. Normally materials cut with a plasma torch include steel, stainless steel, brass and copper, aluminum, although other conductive metals may be cut as well.

Costs of CNC Plasma Cutting Machine:

CNC Plasma Cutting Machine was once quite expensive. So they were usually only found in expert welding factories and very well-stocked private garages and workshops. The Price Range of CNC Plasma Cutting machines is INR 10,000 -1, 00,000 (All Tax Inclusive).

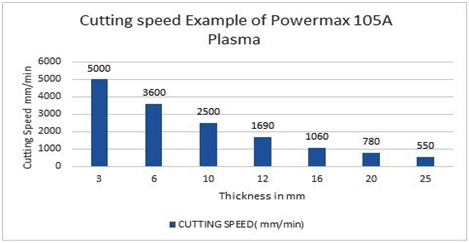

CNC Plasma Cutting Speed Chart

Advantages of CNC Plasma Cutting Machine

CNC plasma cutting machine usages a plasma cutter for cut thin to thick metals along a numerous-axis grid. The CNC process offers a benefit over handheld plasma cutting tools since the cuts are programmed and controlled by a computer rather than by human motion.

- Fast cutting speed, high efficiency, cutting speed up to 10m/min or additional.

- Wide cutting area can cut sheet metal approx.

- Cutting precision is advanced than flame cutting, underwater cutting is not deformed; fine plasma cutting is more accurate.

Features of CNC Plasma Cutting Machine

- Extremely accurate.

- Possibility to cut very thick materials.

- Good cut quality.

- High heat input.

- Wide range of material thickness.