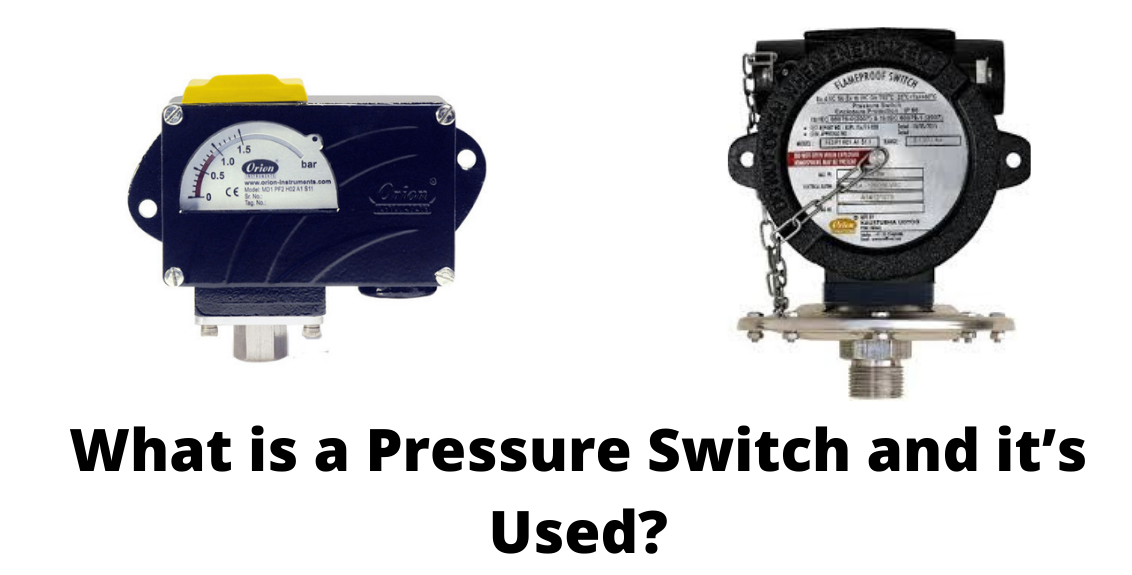

What is a Pressure Switch?

A pressure switch is a device that operates an electrical interaction when preset fluid pressure is reached. The switch types an electrical communication on either pressure rise or pressure fall from a certain preset pressure level. Pressure switches are in a varied choice of industrial and inhabited uses like HVAC systems, well pumps, furnaces, etc.

Pressure Switch is a device designed to display a process pressure and provide an output when a set pressure (set point) is reached. A pressure switch does this by linking the development pressure to a diaphragm or piston to produce a strength that is equated to that of a pre-compressed range spring. Pressure switches, otherwise pressure sensors, are used to offer electrical feedback in response to a chamber either rising or falling to a pre‑determined pressure level being reached. A pressure switch is cast-off to sense the presence of fluid pressure. Best pressure switches usage a diaphragm or bellow as the sensing element. The measure of this sensing element is used to activate one or extra switch links to specify an alarm or initiate a control action. Pressure switches have dissimilar designs with changed detecting elements. One of the most common is unique with diaphragms or bellows as the sensing elements. The one I will discuss here uses a piston as the pressure detecting element. In any case, the operative principle for this piston category is the same with a diaphragm or bellow-type pressure switch. Pressure switches are normally used for a large range of uses through industry and manufacturing. Their function is to provide systems with electrical feedback in response to measuring an increase or decreasing in pressure. A pressure switch is usually modifiable with regard to the chosen set point of operation. We also identified pressure sensors, they are used to respond to fluid pressure.

Where are pressure switches used?

Our products are used in a wide range of industrial and manufacturing uses, such as:

- Well water pumps

- Electronic gas compressors

- In-cell charge control inside a battery

- Starting an alarm if aircraft cabin pressure drops

- Pressure panels on sliding doors

- Switching high streams, e.g., pumps and drives

Types of pressure switches:

- Explosion Proof Pressure Switch

- Flameproof Switch

- Pressure Transmitters Suppliers Manufactures

- Atex Pressure Switch

- Iecex Pressure Switch

- Weatherproof Pressure Switch

- Differential Pressure Switch

- Industrial Pressure Switch

- OEM Pressure Switch

- Pressure Switch

- Low-Cost Pressure Switch

- Pressure Difference Switch

- Compact Pressure Switch

What are the functions of a pressure switch?

Pressure switches are frequently used for a large range of uses through industry and manufacturing. Their utility is to provide systems with electrical feedback in response to quantifying a rise or fall in pressure. A pressure switch is usually modifiable with regard to the selected set point of operation.

What types of applications are pressure switches used?

- Water Pumping Systems: This may be the most common use of pressure switches

- Compressed Air Systems

- Pneumatic and Hydraulic Systems

- Air Conditioning and Refrigeration

- Furnace and Boiler Systems

- Filtering and Screening Equipment

What switches do you supply?

We supply a vast series of switches that can be used in a number of areas:

- Oil

- Air

- Water

- Differentials

- Water pumps

- Compressors

How do pressure switches?

- Mechanical pressure switches usage fluid pressure inside a chamber to activate a physical mechanism, which triggers two contacts within the switch device, either opening or closing the connected apparatus. The pressure point is pre-set as a portion of factory manufacture, and cannot be familiar. Electronic pressure switches will usage electronic signals to trigger the switch, and often provide a secondary indication to monitor the pressure within the designated chamber. Switch actuation points are often determined during factory manufacture but can be familiar as required via an interface on the device, along with extra functionalities.